KBK Crane Installations Requirements, Procedures & Inspections

kbk crane installation safety requirements, procetures, precautions and inspections tips for your reference to make the best value of your kbk rail crane.Flexible combined KBK crane system is a new type overhead travelling crane system with modular crane deigning concept. Crane parts and components of various functions are separated into different modular and the modular with same function are easy to interchange.

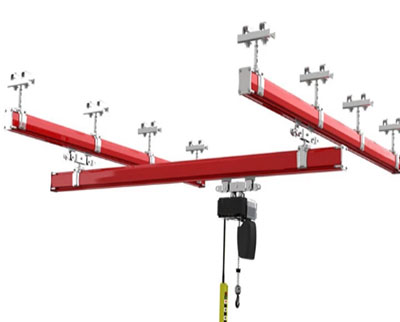

Ceiling mounted single girder kbk crane

Ceiling mounted double girder girder kbk crane

Freestanding single girder kbk crane

Freestanding single girder kbk crane

Safety rules of flexible kbk rail cranes installations

- The installation of the combined kbk crane system should be assembled with the original parts provided by the manufacturer or replaced by the parts with the required dimensions by the original crane factory . Lost parts such as screws, spring clamps, elastic cylindrical pins, pins, etc. cannot be replaced with similar objects at will.

- Prefabricated components (such as crane girder rings, small trolley frame and other welding and riveting parts) cannot be disassembled or modified.

- The bolted connection must be tightened according to the required torque, and the self-locking nut cannot be replaced by other types of nuts; the bolt fasteners must be replaced after five disassembly and assembly; unless the specified tightening torque is too high, it is not allowed to lubricate the bolt fasteners .

- Check whether the spring clamp is correctly installed in the hanger, the spring clamp must pass through the holes of the hanger rod and the ball nut, only in this way the fasteners will not loosen.

- Check the fit of the pinned connection. The notch of the spring pin must face outwards, otherwise it will cause wear.

- The upper suspension of the hanging device and the hinge of the rail clamp must be fully lubricated. Resin-free anti-friction bearing grease should be used, and lubricating oils containing molybdenum disulfide (MoS2) are not allowed. The free movement of the hinge connection cannot be hindered. The kbk crane rail , main beam and electric hoist must all adopt flexible connection methods. Rigid connections can create impact forces that can lead to fatigue fractures.

- When the load is suspended on the cantilever part of the main beam of the kbk rail crane system, check whether the other end of the main beam is lifted up in the air or not. When the light kbk crane is working, the trolleys at either end of the main beam are not allowed to have negative wheel pressure.

- The rail hanger should be exposed and there should be enough space around for inspection and maintenance. It is not allowed to cover the hanging device with other objects (such as: ceiling, etc.).

Installation procetures of KBK crane rail

- Assemble the bowl, cross arm, screw, cue and deck with bolts and cotter pins. The screw is screwed into cue until the cotter pin can pass through the elongated hole in the cue and through the hole in the screw, thread the cotter pin through.

- Install the flexible hanging device on the hoisting track according to the requirements of the scheme drawing.

- Install the kbk crane rail on the bearing steel structure through the flexible hanging device, adjust the flexible hanging device to make it vertical, and adjust the level of the rail by adjusting the screwing depth of the screw and the ball rod.

- Connect the track section into a crane track through two bolts. Note: During installation, there should be no dislocation of the rail interface ends, and there should be no resistance when the trolley is pushed through the joint; it should be ensured that the bolts are tightened reliably and evenly. If the joint bolts are tightened at one end more than the other, the track will bend; the track should not be stressed during installation, as this will narrow the opening of the track; when several tracks are suspended, they must be aligned on the same level straight line.

- Install the anti-collision limit end cover after installing the kbk crane operating device, the suspension line slider and the intermediate buffer into the track.

- Built-in sliding wire kbk railconnecting: first check whether the conductor interface at the interface corresponds, then insert the short end of the sliding contact wire connector into the conductor interface.

Note: the sliding contact wires should be in one-to-one correspondence, and no dislocation is allowed).

Electric wire rope hoist for single girder overhead travelling crane

Electric chain hoist for all type of overhead travelling cranes

Installation of KBK rail hoist

The specific installation steps of KBK crane electric chain hoist

- The chain box needs to be installed;

- Connect the power cord - When connecting the power cord, the power must be cut off in advance. At the same time, the ground wire should be well grounded, otherwise the operator may feel electric shock when touching any part of the hoist or chain.

- Lubricate the load chain of the electric chain hoist - The degree of lubrication of the chain is an important factor affecting the service life of the load chain. Timely and effective lubrication of the load chain can ensure the effective service life of the chain.

- Check the alignment of the chain - For electric chain hoists with multi-row chains, it should be ensured that the lower hook frame is not turned over. If flipped, return it to its normal state, making sure the welded joints of the chain line up. Never hang a load on a hoist with a twisted chain.

- Check the working voltage - Since the electric chain hoist is equipped with the voltage specified by the user or a higher voltage (only for dual voltage) when it leaves the factory, such as 230/460V, it is necessary to check the wiring and confirm whether it meets the requirements of the power supply voltage.

Matters needing attention on kbk crane hoists

- The installation position of the electric chain hoist lifting ring must ensure that the hoist power supply wiring inlet is facing the power supply direction.

- Connect the lifting ring of the electric chain hoist to the bearing pin of the trolley and fix it with an elastic cylindrical pin.

- Make sure that the pin opening of the elastic pin is outward, otherwise it will cause wear. When re-installing the hoist, it is necessary to replace the elastic pin with a new one.

- For other information on assembly, installation, putting into use, operation and maintenance, please refer to Kaili Hoist's "Electric Chain Hoist Product User Manual".

- Connect all cables according to the electrical control wiring diagram, and install appropriate fuses to connect to the power supply.

- The rail terminal of the safety sliding contact line uses a special wiring pin, and is connected to the power supply according to the specified sequence. Note: The center conductor of the trolley line must be the grounding line.

- All cranes must have the manufacturer's mark and the rated lifting capacity mark on both sides of the track (main beam).

- The rated lifting capacity of the hoist must be consistent with the rated lifting capacity of the track.

Installation and wiring of kbk electrical installations

- First install the electrical control and crane switch box, and then wire according to the wiring diagram.

- NOTE: Make sure that the flat cable is not twisted along its length when installed. Firmly tighten all nuts and bolts at the cable anchorage points.

Precautions when installing kbk rail system

Nowadays, many large-scale production and processing plants have installed kbk rails to lift heavy objects. However, what should be paid attention to when installing kbk rails?

- The installation and use of the kbk rail requires the use of a hexagonal socket wrench to ensure that the track can be installed smoothly.

- When the track is installed, the plan should be designed first, and the workers should operate according to the installation requirements to meet the needs of customers.

- Do not choose a place with steps for the track connection port, so as not to affect the operation of the crane during operation.

- Do not tilt the track installation, make sure it forms a straight line, so as to ensure the smooth running of the track.

- When installing the track, tighten the screws and do a good job of fixing to avoid danger during the operation.

The above are the precautions for kbk railinstallation. If you have other questions, you can call for consultation.

Precautions of kbk rail bolt installation

The kbk rail is used for lifting heavy objects in the factory workshop. The track system is simple to install and easy to debug. The standard modules can be connected with bolts. Bolts play an important role in fixing the track. If the bolts are loose, it is likely to cause major safety accidents and the consequences are very serious. Therefore, more attention must be paid to the selection and installation of bolts.

- Under normal circumstances, the bolt grade should not be lower than 8.8. On some special rail connection points, ordinary bolts cannot be selected, but double-nut bolts should be installed to ensure the firmness of the installation of the rail system.

- After all the bolts are installed, careful inspection should be carried out to prevent the bolts from not being fastened during the installation process.

Inspection of after completing kbk crane installation

After completing the assembly work, crane inspection is required to ensure:

- The trolley runs smoothly when passing through the track joint.

- The conductors of the trolley line are correctly connected .

- The contact of the collector is safe and reliable;

- Drag cable has sufficient length.

- The safe distance of the crane between the buildings and other machinery is adequate.

- The color of the protective grounding conductor shall be yellow and green. The grounding protective conductor is not allowed to be connected to the bolts used for connecting parts, and the grounding connection should be connected with special anti-loosening screws. The grounding protective conductor is not allowed to conduct working current.

- A power switch should be installed to control the on-off of the crane circuit, which should be able to cut off all phase wires of the crane electrical system. The switch should be located close to the kbk crane and easily accessible by the operator.

- If more than one lifting device is powered from the same power source, an isolating switch should be installed on each device. This isolation switch allows each device to be maintained separately without affecting the use of other devices.

Types of KBK crane systems for your selection

KBK light crane system includes KBK monorail suspension crane, KBK single girder suspension crane, KBK double girder suspension crane, KBK telescopic girder suspension crane, KBK stacker crane, rigid kbk crane system, and combined-type KBK cranes, and other forms, etc.